Are you looking to improve efficiency within your CPE returns management process? A sluggish process can lead to poor turnaround times, cost deficiencies, and lower customer satisfaction.

Ingram Micro Lifecycle works with manufacturers and providers of Customer Premises Equipment to provide repair and refurbishment solutions. Our returns management programs employ technical experience and know-how to improve processing speed, quickly turning around assets for reuse or sustainable disposition.

This article covers how automation and robotic technology can be used within returns management to enhance processing.

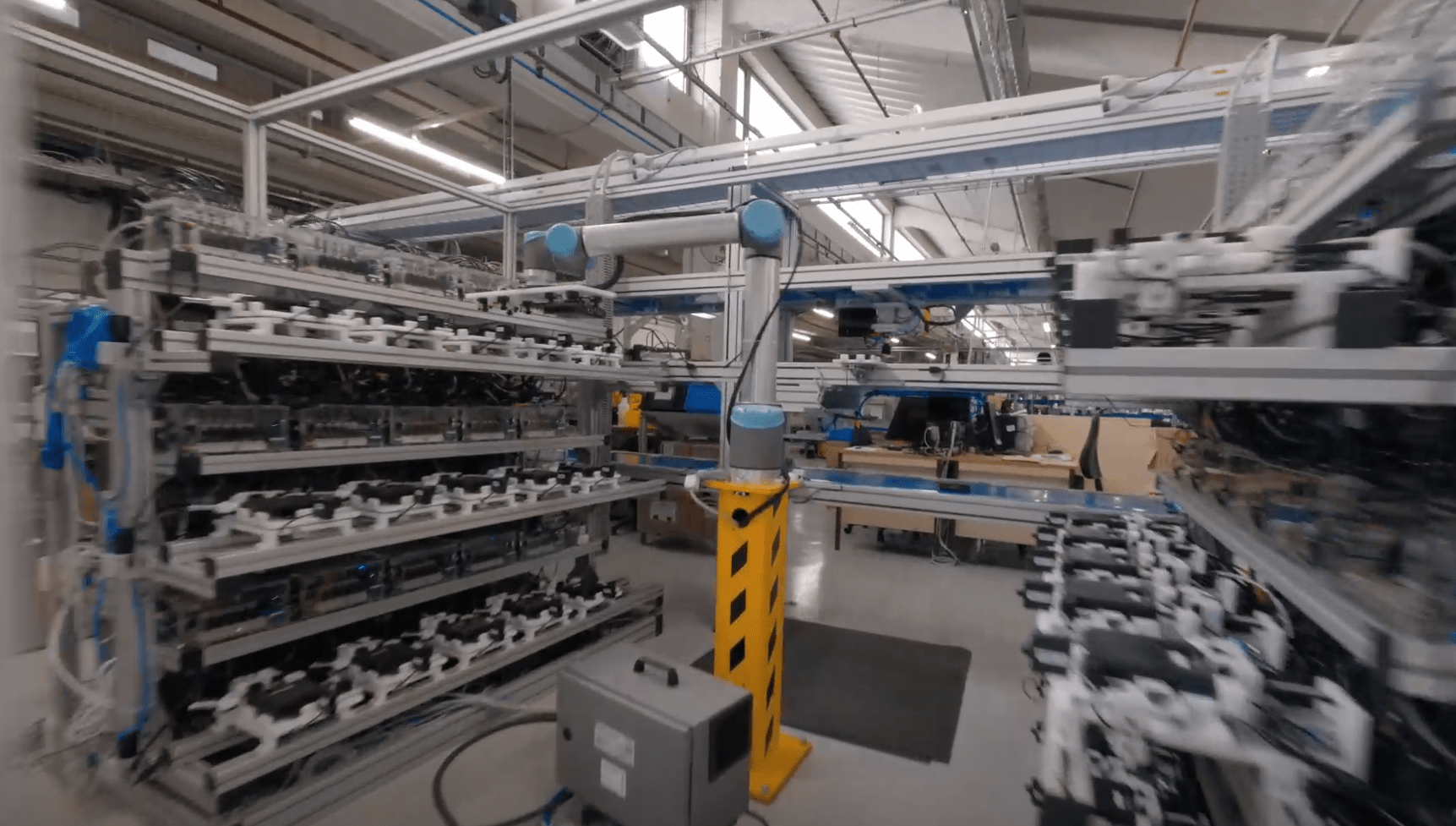

Automation and robotics in CPE returns

Using advanced technology in your CPE returns management has multiple benefits, which we cover below. Recent developments in artificial intelligence and machine learning are advancing warehousing solutions and processing. This is important when you consider the volume of returns that occur daily. As consumerism grows, so will the need for more comprehensive and efficient returns processing solutions.

We’ve previously discussed the implications of slow turnaround time on customer satisfaction, and, while the return of CPE may not have as big of a financial impact on end users as retail purchases, it can still impact their satisfaction.

Ways robotics and automation streamline CPE returns management

- Sortation of returns. Robotic arms and carts can sort, stack, and deliver packaged returns to workstations ready for inspection.

- Moving units. Lifting CPE products onto conveyor belts before and after testing, and filling pallets with repackaged units after repair and refurbishment have been completed.

- Loading of smaller parts into jigs. If you have custom-made jigs for different parts to be tested (for example, batteries of wireless routers) then robotics can take the strain of selecting smaller parts and repetitively loading these into jigs for testing.

- Cameras. These use machine learning programs to make processing decisions quickly based on a predetermined logic.

- Separation for quality control. During the testing process, automatic arms filter the passes and failures on conveyor belts, ensuring that only passes proceed to the next step, while fails are routed differently.

- Packaging. Putting boxes together can be done robotically, removing the strain of this repetitive and mundane task from human responsibilities.

- Ancillary testing. This process checks power supply units (PSUs), cables, and RCUs for product preservation. This includes testing voltage, noise levels, insulation, button functionality, connectivity, and continuity.

- Polishing. This restores the condition of outer plastic casing. Plastic waste can be a huge issue in returns management, not only for CPE but all kinds of electronics. One way to minimize this is in the refinishing of plastic components to a clean and like-new condition. Robotics are used to place CPE into custom jigs for the automated polishing.

The benefits of including automation and robotics in CPE returns

We’ve touched on some of these above but there are several key benefits that you can take advantage of when incorporating automation and robotics into your CPE returns management processes.

While there is discussion about whether these will replace human intervention, we see robotics as a collaborative development. These can enhance the manual work of technicians as they remove the more dexterous and repetitive tasks, boosting the health and safety of workers. Not only that, but the robotic systems can complete these tasks at a higher rate, delivering an increased successful yield, and alleviating the pressure of this responsibility.

Artificial intelligence tools also allow for a more seamless application of consistent rules and requirements, removing human error and subjectivity. The software- and hardware-based technologies make it easy to upscale operations and roll out to other facilities or locations. With the right minds behind your solutions, you can tweak programming to create bespoke processes.

Boost your CPE returns management

Robotics and automation can be added to your CPE returns handling processes to assist with sortation, routing products to the correct step, efficiently assessing product functions, and more.

Ingram Micro Lifecycle has developed bespoke solutions for CPE customers that include both robotics and automation to boost yields and turnaround times. These custom returns management services are underpinned by our global footprint, over a decade of experience, and rich technical knowledge.

Get in touch with us today to discuss your returns management needs and how we can boost your NPS and deliver faster processing times.

Related articles: