Are you concerned about the environmental impacts your IT estate will have on the environment when it’s no longer useful? Perhaps you’re looking to make sustainability changes across your IT usage.

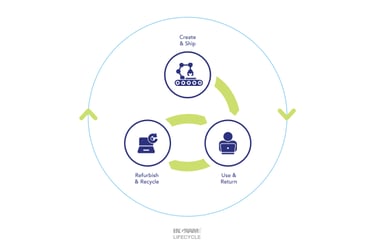

Ingram Micro Lifecycle works with businesses worldwide to manage the lifecycle of IT and technology assets. Our end-to-end services streamline repair and refurbishment processes to maintain and prolong the useful life of technology.

In the piece below, we discuss the ramifications of e-waste and how your business can reduce its e-waste.

What is e-waste?

The European Union defines e-waste simply as waste electrical and electronic equipment. It covers products that have a plug or battery and have been discarded. While technology expands, so does the range of consumer goods that can become e-waste. This now includes VR headsets, smart home devices, and sound systems.

Business equipment contributing to the volume of e-waste includes internally used technology such as servers, laptops, and smartphones plus any customer-supplied equipment, particularly for consumer technology manufacturers.

What are the impacts of e-waste?

When used technology is informally disposed of, it usually heads to landfill. Here, the components don’t break down and continue to build up over time. Some material decay can cause substances, such as lead, mercury, and brominated flame retardants, to leak into the soil and atmosphere, contaminating the surrounding area.

Although the Basel Convention makes it illegal to ship e-waste to less developed countries, there are still huge e-waste sites in these countries. In these locations, people often sift through the waste to find components and materials that may be worth money. This physical handling and proximity to decaying technology causes health problems including neurological damage, cancer, and burns.

There’s also a loss of resources. Raw materials are mined to produce new goods and the opportunity to reclaim these is lost if the product goes into landfill. The strain on natural resources is high for the production of electronics and there are also high carbon emissions associated with this activity.

These negative outcomes of wasting technology can be reduced with better management.

What are depot services?

Depot services are a comprehensive package of asset management solutions that ensure a more efficient use of technology. These include asset configuration and fulfilment, advanced exchange, refurbishment, re-kitting and stocking, and ITAD.

How depot services help reduce e-waste

These services are offered to enterprises to extend the lifecycle of their IT suite for as long as possible. These assets are products they use themselves, such as company-provided smartphones or laptops that enable employees to work with agility.

Typically, these are everyday-use products (or at least, every weekday) and get a lot of wear and tear. The solutions within depot services process these technologies to keep the standard and quality high, making their use more effective for longer. This extends the refresh point when a brand-new replacement is needed (or even a refurbished replacement). Maintaining the state of the equipment delays the point where it will eventually become e-waste.

Using your equipment for longer also saves your business money. You don’t need to invest in brand new assets as often, and instead cut costs through continuing to use existing equipment. Depot services ensure that repair and refurbishment processes are used only when necessary.

Another benefit is that avoiding new purchases boosts your sustainability and lowers the carbon footprint of your assets. The manufacturing of new technologies uses precious raw materials that need to be mined, causing the depletion of these natural resources. The process of mining and manufacturing causes carbon emissions. If you were to continue using refurbished technology only, you’d be eliminating those supply-associated emissions from your footprint.

Where your equipment cannot be efficiently or cost-effectively restored to good working order, these assets should be compliantly disposed of by your depot services partner. This means assets should be securely data wiped, providing you with an auditable trail, and recycled. Data wiping is essential to avoid illegally breaking data protection laws or leaking proprietary business information. It’s possible to recover individual parts and components from units for reuse in other similar products, which lowers the cost of repair.

When the time does come to upgrade your equipment, the tech you have can be assessed for any potential value recovery. Repair and refurbishment techniques uplift the value and condition of the product ahead of recommerce on the secondary market. This recovered value could be used to offset the cost of new purchases.

As hybrid and remote working is becoming readily accepted as the new normal, it’s important to keep an accurate record of just where all your company-owned assets are. Your depot services partner will do this. It becomes their responsibility to onboard new joiners to your company, configuring and despatching the necessary equipment. They’ll also reclaim technology from leavers. The depot service processes restore the technology and ready it for the next user, completing a robust data wipe and returning it to good working order for reuse elsewhere within the company.

How manufacturers can support the reduction of e-waste

The repair and refurbishment of all products should be considered at the design stage. This increases the ease with which a product lifecycle can be extended. For example, using glue instead of screws makes it more difficult to repair a product without causing additional damage. Consider product longevity from a circular economy standpoint, factoring in easy refurbishment, repair, and reuse.

As well as making the process easier, robust guides can be created to demonstrate the best ways for repair and refurbishment partners to extend the lifecycle of a product.

Reduce your corporate e-waste today

Through more efficient management of your technology assets, you can reduce your e-waste contributions. Manufacturers can strive for repairability of their products, and through combined efforts, lifecycles of technology can be extended, reducing pressure on raw materials, alleviating carbon emissions, and boosting sustainability.

Ingram Micro Lifecycle offers a comprehensive package of depot services that provide value recovery, environmental stewardship, and risk mitigation benefits. Our lifecycle support and ITAD services ensure the full life of your IT assets are catered for efficiently and sustainably.

Contact our team today to learn how we can help you reduce your e-waste.

Related articles: