Are you looking to understand the sustainability impact of your reverse logistics process? If you want to make your activities more sustainable then optimizing reverse logistics has huge potential benefits.

Ingram Micro Lifecycle is a third-party logistics provider, supporting customers in different industries with their technology requirements around the globe.

Our services enable a circular economy while also working to recover the maximum value without compromising sustainability efforts.

Below, we introduce the reverse logistics process and outline the three main pillars of sustainability before tackling how reverse logistics impacts the first of these pillars.

Understanding reverse logistics

Reverse logistics is a driver for operational efficiencies. Retrieving products and returning them to a functional state is only half the story.

Getting those returned products to working order leads to swap pool creation and volumes. This can damage your sustainability process as then there’s new packaging and peripherals to consider, which adds to waste creation via replaced plastics.

However, when optimized and considered with sustainability in mind, reverse logistics can advance sustainability goals, supporting the three sustainability pillars.

There is potential for sustainability achievements in reverse logistics to feed into sustainability objectives across the whole supply chain, not just within the one process department, but also by extension to customers.

First, let’s understand what reverse logistics is.

What is reverse logistics?

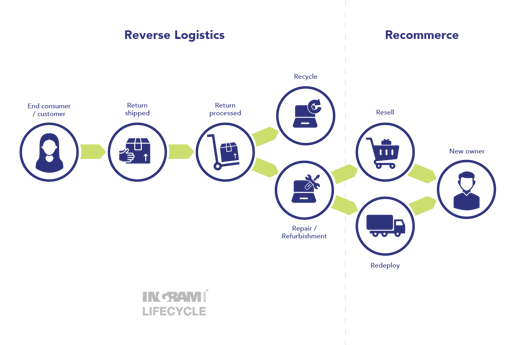

Traditional logistics, specifically forward logistics, is the process of moving the goods from the manufacturer to the consumer or end user.

Reverse logistics therefore, is the opposite of this movement, and is the control and flow of goods from the consumer or end user back to the originating sales point, distributor, or manufacturer.

Reverse logistics also involves activities that identify and trigger strategies that can impact and prolong a product's lifecycle.

These activities prevent a perhaps untimely end for the product, thus avoiding becoming e-waste. Reverse logistics is a gateway to enabling a circular economy and closing-the-loop practices.

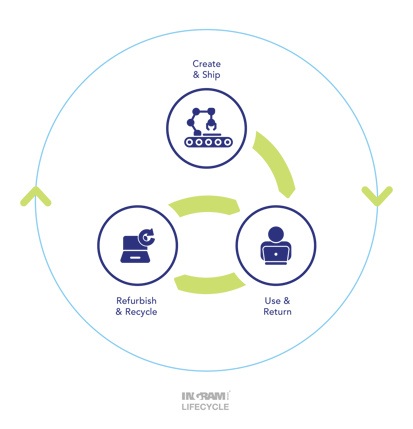

Moving towards circularity

The European Parliament describes a circular economy as, “A model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible. In this way, the life cycle of products is extended.”

Through reverse logistics, products, typically otherwise intended to become waste, can be assessed, graded, and green-lighted for various repair, refurbishment, and recommerce activities, providing an additional shot at a useful life.

According to the Reverse Logistics Association, returns in the US generate 5.8 billion pounds of landfill waste every year, 16 million tons of carbon dioxide, and produce $761 billion in lost sales.

With online purchases facing an average 21% return rate, there is a wealth of opportunity for lifecycle extension tactics, minimizing the negative environmental impacts and salvaging potentially lost revenue.

The three sustainability pillars of reverse logistics

When we talk about the three pillars of sustainability in reverse logistics, we refer to the three distinct benefit categories:

- Environmental – eco-friendly practices such as recycling and reuse of materials, reducing the volume of harvested raw materials for manufacturing.

- Economic – including the monetization of assets and harnessing new revenue streams.

- Social – the fair labor practices within reverse logistics roles.

The environmental pillar of reverse logistics

The global population is waking up to the impact that our everyday activities have on the environment. We’re surrounded by facts about polar ice caps melting, the reduction of raw materials and minerals, the plastic in our oceans, and much more. Carbon emissions, excessive natural resource depletion, and solid waste disposal are the main sources of environmental degradation and global warming.

Technology is ever-changing, ever-improving, and therefore ever-being-replaced. Materials are needed to fuel these improvements, not just in componentry but also in production. The manufacturing and production sector contributes one-fifth of all global carbon emissions.

E-waste can have a huge detrimental effect on the environment if not handled correctly. It can be toxic or hazardous if left to decay and break down in landfill, contaminating the soil. As the make-up of our technology evolves, so too must the processes for responsibly handling it when it becomes waste.

Reverse logistics is the first step in extending a product's lifespan, minimizing production, conserving natural resources, and reducing carbon emissions.

Some businesses may just offer the manufacturing part or the remarketing part of reverse logistics, but combining these into one end-to-end solution is key to ensuring the waste from scrapped products is minimized as far as possible. Up to 40% of products can be salvaged and given a second life, enabling businesses to realize revenue and minimize the negative environmental impact of their products.

Here are several ways reverse logistics supports the environmental pillar.

Repair and refurbish

Reverse logistics has a huge part to play in mitigating the negative impacts of our technology usage on the environment. As stated in our opening, reverse logistics can incorporate the vital step of assessing product condition and determining which products are suitable for salvaging. It therefore triggers responsible steps to repair, restore, and recycle as much as possible to cut down on waste that goes to landfill.

Replacing plastic parts is suboptimal, particularly for environmental considerations. Processes that refinish plastic or glass, such as DSP (Diamond Substrate Processing) and LCD repair, and all supplementary solutions around specialist cleaning, ensure you’re not bolting on additional material and creating a new waste stream.

This supports the conservation of materials, reducing the pressure on the harvesting of raw ones.

Swap pool management

If done correctly, swap pools don’t have to incur huge plastic and parts wastage. Through repair and refurbishment processes, you’ll already be cutting down on the new parts needed, as you’ll be refurbishing what you already have or perhaps using donor parts.

This provides you with a higher-quality swap pool of used devices, reducing the need for the purchase of new ones, and alleviating your reliance on the manufacturing of complete devices.

Using repaired and refurbished devices within your swap pool helps balance the supply chain.

Trade-in programs

Trade-in programs enable customers to bring used products to exchange for cash, credit, or discount off a new purchase. These types of schemes are typically offered by manufacturers or retailers, and use reverse logistics to get the product back to a processing center for assessment.

These products can then be restored to a saleable or reusable condition. Without the trade-in scheme, the end user may have placed the product into general waste, or perhaps recycled at a designated facility.

Alternatively, they may have left the product in storage, forgotten in the back of a cupboard to gain dust. Through trade-in programs, the products have a better chance of being handled responsibly and the lifecycle extended.

Return policies

As an evitable part of sales, there’ll always be a percentage of products that are returned under the terms and conditions of sale. This can be for a variety of reasons, ranging from customer change of mind to product fault. 60% of returns are caused by the merchant.

The process followed under the returns policy has an environmental impact. The choice of shipping that the consumer has affects this. For example, offering a home collection can increase carbon emissions as there are a higher number of single, specific journeys being made.

The aim should be to minimize the impact of transportation through fuel consumption and emissions. This can be mitigated by the introduction of electric vehicles and the consolidation of collections.

Establishing Pick-Up/Drop-Off (PUDO) locations enables aggregated returns in a convenient location that the end user would be likely to visit anyway, rather than take a specific trip, so products can be collected in batches.

There’s also the free vs fee return debate. If you remove the free return option and charge your customers a processing or handling fee instead, will this minimize the potential of unnecessary returns? Fewer unnecessary returns reduce the volume of products within the reverse supply chain and alleviate the environmental impact.

Improve your environmental impacts

We’ve given a top-level overview of what reverse logistics is and introduced the three pillars of sustainability. In covering the environmental pillar, we explored the impacts that e-waste has on the world around us and how extending the lifecycle of devices can reduce the dependency on raw materials.

Ingram Micro Lifecycle are market-leaders in reverse logistics, working to create solutions through innovation that enable a circular economy for our customers’ technology.

Look out for the next article in the series when we’ll be discussing the next sustainability pillar, economic. In the meantime, if you want to discuss how our reverse logistics solutions can alleviate the pressure on your business, get in touch.

Recommended reading:

- Reverse logistics opportunities to transform returns into revenue

- Reverse logistics: the economic pillar of sustainability

- Reverse logistics: the social pillar of sustainability

- What is reverse logistics? Definition, types, and benefits

- 7 reverse logistics challenges for small domestic appliances

- 7 ways to optimize technology reverse logistics

- Steps your business can take to reduce e-waste contributions

- 6 benefits of a circular economy

- What is e-waste and the environmental toll of our tech habits?